X-Ray

Useful for finding die position in packages, looking into epoxied modules, etc

- Horiba XGT-7000 X-Ray Analytical Microscope XRF w/ Processor Controller

Contents

Sensor

DIY using DSLR: https://twitter.com/FauthNiklas/status/967192093318942720

Digipan reverse engineering: https://hackaday.io/project/62710-taking-digital-xray-shots-for-cheap-300/details

Digital intraoral

Gendex GXS700 / Dexis Platinum USB sensor

Kodak / CareStream RVG 6100 USB sensor

Digital body

https://www.youtube.com/watch?v=QSVJtwehwho

- "Digital x-ray panel sensors, teardown & reverse-engineering"

- Canon CXDI-701C

Someone also mentioned Varian and Trixell

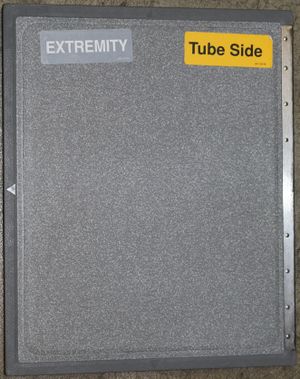

Intensifying screens

Introduction to screens (ref):

- standard

- slow

- calcium tungstate

- rare earth

- fast

- gadolinium or lanthanum

- Commercial brands: Kodak Lanex

Details on different phosphors: http://www.pocketmagic.net/x-ray-intensifying-screen/

There's a good vendor summary / cross reference chart here: [1]

I think the number following the name is generally the gain. That is a 400 screen will put out twice as much light per x-ray as a 200 screen They call this the "speed" presumably because it makes film expose faster. Chart here

Brands:

- 3M

- AGFA

- DUPONT/STERLING

- FUJI

- JPI

- KIRAN

- KODAK

- Lanex: rare earth green

- KONICA

- MCI OPTONIX

Following sections are for screens I own. Basically they were cheap on eBay

Intensifying tube

was offered a broken tube but I don't think it would have been useful

Aha! I got offered a working tube. And thus children have nightmares now

Source

| Image | Vendor | Model | Type | Note |

|---|---|---|---|---|

| GE | 1000 | Tubehead | ||

| Eureka | Emerald 125 | |||

| Eureka | RA51-1.5 |

Rotating anode systems

Include:

- DUNLEE 180-00

- Rigaku Denki Rotaflex Rotating Anode X Ray 4363 F Cu Shutter Control Assembly

- RIGAKU, MICROMAX 007HF 4364F501

- Transworld 325v

- Craigslist freebie

- Varian Medical Systems RAD-99B tube

- VARIAN G-1086, Housing Type B-160H

- Varian RAD-21 VMS SAPP-150KV

- 8000-3488 UNIVERSAL UNI-MATIC 325D GENERATOR MODEL NO. 3488/3550

- GE Medical Systems AMX4 Portable X-Ray

- EUREKA DIAMOND 150 X-RAY TUBE

- EUREKA MODEL EMERALD 125 X RAY TUBE !! K366

Machine

Things that are more than just a simple head or sensor: airport scanner, PCB inspection, etc

DIY x-ray setups

Ben K x-ray, CBCT "chicken" setup

- originally unshielded but I think is now?

- In CBCT mode runs automatically via arduino and thus person doesn't have to get exposed

Russian fellow: http://habrahabr.ru/post/254015/

- ...who gave himself acute radiation sickness. A stern warning to those not taking such a setup seriously

John M dental x-ray setup

- which has about 100 lbs of lead shielding

- also operated remotely via ssh to laptop

mcmaster rotary stage replacement

Goal: stop using my Sherline rotary stage and instead use spare CNC rotary stage (from laser machine purchase lot)

Motor: Vexta PH566-B 5 phase stepper

Controller: Rorze RD-053MS

- Datasheet

- Spec sheet

- Has a lot of pins labeled

- Enclosed in box with cable running to the rotary table

- 3 per box

- Need to interface to output Centronix connector

The left side connections are pretty obvious:

- power

- 18V to 40VDC

- motor phases

Left side less so

- diff1

- diff2

- 4P IN

- FREE

- PHASE OUT

- ALARM OUT

Summary

- Up to 400 microsteps/step

- Current driven...looks like approx. 3.8mA at 5VDC?

- 3.3V compatible?

Two ways that step/direction can be configured

Two Clock Input (2CK) (Inputs two clock pulses - CW clock pulse and CCW clock pulse)

- CW+/-: Motor rotates in CW direction with a pulse current of 8 to 20mA from CW+ to CW- terminal.

- CCW+/-: Motor rotates in CCW direction with a pulse current of 8 to 20mA from CCW+ to CCW- terminal.

One Clock Input (1CK) (Inputs clock pulse and direction (CW, CCW))

- CLK+/-: Motor rotates in CW direction with a pulse current of 8 to 20mA from CLK+ to CLK- terminal and UD input off.

- UD+/-: Motor rotates in CCW direction with a pulse current of 8 to 20mA from CLK+ to CLK- terminal and UD input turned ON.

Basically it looks like second is standard step/direction configuration

- Yep buried in later documentation: Selects clock input, Two clock input method (2CK) or Pulse & Direction input method (1CK).

6-2 Full Step Input (4P IN +/-): Motor rotates in full step mode with a pulse current of 2 to 10mA (approx. 3.8mA at 5VDC) from “4P IN +” to “4P IN –”

6-3 Free Input (FREE +/-): The excitation current of motor will become 0 and a motor can be rotated by hand with a pulse current of 2 to 10mA (approx. 3.8mA at 5VDC) from “FREE+” to “FREE-”.

- NOTE: Do not turn this input ON when motor is running at high speed, this operation would

damage the amplifier circuits.

6-4 Phase Output (PHASE OUT+/-): PHASE OUT output (open collector output) is turned ON at the phase home. One pulse is put out every time the motor moves 7.2゚ in case of 0.72゚ motor. The Duty of output ON is 10%.

6-5 Alarm Output (ALARM OUT+/-): Overheating protection circuit intervenes turning ALARM output ON. (Open collector output ON)

All channels as given are configured the same

- 8-1 current range: 1.5A

- 8-2 clock select: 1 clock

- 8-3 auto current down: on

- 8-4:8-8: microstepping: 32

- D1: 0

- D2: 1

- D3: 0

- D4: 0

- D5: 1

- 1: to the left, 0: to the right (assuming OFF => 0)

Agilent PS test on CLK input while off (assuming its just a PD)

- 0V 3 mA (subtracted from all other values)

- 3.3V: 7 mA

- Just under recommended 8mA...maybe I can get away with it for now but long term need to boost it

- 8 mA: 3.5 V

- 5V: 13 mA

- They said 3.8 mA...are inputs non-uniform?

- 20 mA: 6.8 V

(note to self: script a curve tracer...)

BBB test:

- red: STEP+ to P8.13

- black: STEP- to P8.1

- white: DIR+ to P8.12

- blue: DIR- to P8.2

no response

try agilent supply tragging step input

- 3.2V: no step

- 3.3V: step

Its just too close on the edge for it to work I guess

- This does verify I'm on the right channel