Difference between revisions of "User:Mcmaster/Fusor"

(Tag: Visual edit) |

(→2019-04-29) (Tag: Visual edit) |

||

| Line 535: | Line 535: | ||

General feedback from people at party a few weeks ago: | General feedback from people at party a few weeks ago: | ||

| − | * Make inner electrode smoother. Its probably the cause of the arcs | + | *Make inner electrode smoother. Its probably the cause of the arcs |

| − | * Consider removing outer electrode. It probably doesn't do anything | + | *Consider removing outer electrode. It probably doesn't do anything |

| − | * Smaller MFC (say 50 SCCM => 5 SCCM) | + | *Smaller MFC (say 50 SCCM => 5 SCCM) |

| Line 545: | Line 545: | ||

TODO: | TODO: | ||

| − | * Troubleshoot new MFC. Why can't I get it to actuate? Check output voltage | + | *Troubleshoot new MFC. Why can't I get it to actuate? Check output voltage |

| − | * Test, cable AD 704 | + | *Test, cable AD 704 |

| − | * Proper HV connector | + | *Proper HV connector |

| − | <br /> | + | <br />MFC on benchtop supply |

| + | |||

| + | * +15V: 70 mA | ||

| + | * -15V: 100 mA | ||

| + | * Green light blinks | ||

| + | |||

| + | Got MFC working. Valve full open w/ turbo + scroll pump backing => 4.0E-2. With valve closed get around 2.0E-3 (unclear if turbo is bad or gauge can't read low well). Can probably close a downstream valve if I want to raise pressure further | ||

Latest revision as of 06:10, 30 April 2019

Contents

- 1 Milestones

- 2 BOM

- 3 Neutron detection

- 4 D2 bottle

- 5 MFC

- 6 2011

- 7 2015-10-24

- 8 2015-10-25

- 9 2015-10-26

- 10 2015-10-31

- 11 2015-11-01

- 12 2015-11-02

- 13 2015-11-03

- 14 2015-11-04

- 15 2015-11-05

- 16 2015-11-06

- 17 2019-04-29

Milestones

Main system

| Objective | Completed | |

|---|---|---|

| Old project | 2011 | |

Schematic: baseline EE/mech |

2015-10-26 | Lots of changes since |

| Schematic: order parts | 2015-10-29 | How to hook compressor up for MFC test? |

| Schematic: recieve parts | Stalled: ord F-F VCR. Only have M-F | |

| Schematic: assemble vacuum | Tech demos before full assembly? | |

| Schematic: assemble electrical | Tech demos before full assembly? | |

| MFC: demonstrate under computer control | ||

| MFC: simulate D2 operation | Test gas? He? H2? | |

| HV: plasma test | Demonstrated in past | |

| Fusion test |

Detection

| Objective | Completed | |

|---|---|---|

| GM tube on scope | ||

| He-3 tube on scope | Consider raising voltage to GM region (1.5 3 kV) LKB PS grounding can't scope. Workaround: NIM PS | |

| He-3 tube on PC | PoC with GS | |

| GS: schematic | SKIP | Better understand current limiting |

| He-3 on GS? | SKIP | Early tests indicate GS is probably a poor fit: insufficient voltage, insufficient documentation Pro version even more expensive…not worth it |

| He-3: computer capture | Figure out amplifiers, etc to make PC capture work | |

| FOSS capture | Look into existing projects if worth using | |

| Audio: Linux capture | Want to move away from the Windows SW for better control | |

| Audio: Linux MCA | Demonstrate MCA capabilities…maybe using NaI / GS | |

| He-3: Am-241 + Be: neutron detection | What sort of Be do I need for this? Moderate? Need to read up more on | |

| He-3: Am-241 + Be: gamma discrimination | Lots of lead shileding sounds the easiest |

BOM

Neutron detection

D2 bottle

Label

D25030004 CGA180/110 06N PC 2011/10 MADE IN LUXEMBOURG 10 B

Outer thread

- Tapered

- Ordered (I think) SS-8-VCR-7-6 (3/8 NPT to 1/2 VCR) which doesn't fit

- Thought it was 3/8" NPT but not

- 18 TPI => 1/4 or 3/8 and its not 3/8

- Must be 1/4

- Order SS-4-VCR-7-4 (1/4 NPT to 1/4 VCR)

Inner thread

- Had cap in it originally

- Male: 0.3" OD

- Fine thread (28 TPI?)

- Not tapered

MFC

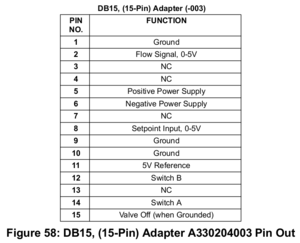

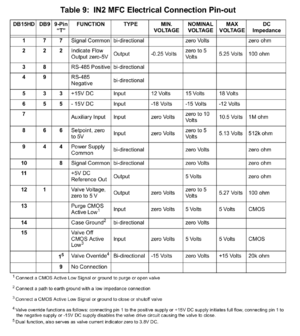

1, 9, 10 are tied together. 14 is not

Green light should come on. I had one unit that didn't power on due to the case falling apart, pulling out the plugs between the DB connector and the main assembly. Re-plugging it fixed the unit

Mine: turn pot CCW to close valve

Reference current draw

- CH3F unit

- +15: 72 mA

- -15: 75 mA

- CHF3 unit

- +15: 67 mA

- -15: 74 mA

2011

2015-10-24

Someone local interested in building one. Reviving an old project.

This also coincides with a test I'd like to run in a few weeks. Aggressive schedule: try to generate neutrons (even if low flux) by 2015-11-15

Inventory

I have parts leftover from this project 6 years ago plus stuff I've accumulated since then. Includes:

- MFC's (see below)

- Chamber

- CF600 full nipple

- CF600 Cluster flange (4x CF133, 1x CF275)

- CF600 saphire window

- CF275 HV feedthrough (made by me)

- Inner and outer grid assembled from previous run

- 1 TC gauge

- Don't have the meter anymore. Probably will toss

- 100 mL heavy water

- 10L D2: Sigma Aldrich 368407-10L (new / unopened)

- MFCs: see below

- Turbo pump (KF40 inlet, KF16 outlet)

- Varian DS-42 roughing pump (KF16)

- KF16 inlet

- Neutron detection

- 2x large Russian neutron tubes

- 2x small Russian neutron tubes

- Calibration

- Am-241 samples

- Be metal

- Tritium detection

- Tritium exit light tube

- Misc Geiger counters…useful?

Need to acquire:

- Foreline trap

- Preferably KF16 but KF25 would probably also be fine

- Avoid KF40 (although it seems to be common)

- KF16

- MDC KTX-075-2: [2]

- Made offer for one used on eBay (hopefully still useful…)

** Offered $37

- $245.00 new

- KF25

- MDC KTX-100-2: [3]

** 430051 - Coaxial Trap, 4"Body, NW25 ** $267.00 new

- MFC: HD15 female breakout board

- Get just one or max out by getting 3?

- Get at least 2

- Ordered 3x off of Amazon ($6.99 each)

- Board to drive analog MFC

- Start with STM32F4DISCOVERY: SMT32 has on board DAC + board has second for audio

- Ordered 2x off of Digikey ($15.83 each + S/H)

SCCM requirements

fusor.net

"My fusor consumes D2 at about 1 sccm in continuous-flow mode. The cost of gas has been minor in comparison to everything else in the system."

"For fusion, you will need to adjust a pressure of 12-15 mTorr"

http://www.fusor.eu/reactor.html

TLDR: 1 SCCM target. Used 50 SLM MFC?

"The MFC should ideally be calibrated for hydrogen and be able to deliver a flow with a minimum quantity of 1 SCCM (standard cubic centimeter per minute), which is the flow of Deuterium that a Fusor requires. The MFC as shown in the images has a capacity of 50 standard liters per minute"

prometheusfusionperfection

"20 SCCM SEC 4400 Mass flow controller $88"

- Presumably this was used for the fusor

MFC inventory

Summary

| Vendor | Model | Interface | Gas | SCCM | |

|---|---|---|---|---|---|

| Unit Instruments | SNA1453049300 | DeviceNet | N2 | 20 SLM? | |

| Millipore | FSDAB100CKLR | HD15-M | CF4 | 200 | |

| Millipore | FSCAB100BXLR | HD15-M | CH3F | 50 | |

| Millipore | FSDAB10014LR | HD15-M | CHF3 | 100 |

Unit Instruments

UNIT UFC-8165 20L N2 303-03618 SNA1453049300 CAl#:D43970 Resp:F Attd:HOS Exh:V Valve:NC Ref:0C Ref:760TORR Conn:DvcNet Opt:AS CSR:0559IntelliFlow FSDAB100CKLR

IntelliFlow FSDAB100CKLR

IntelliFlow Digital Flow Products MODEL NUMBER FSDAB100CKLR GAS: CF4 RANGE: 200 REF: SCCM SELECT: DATE: 10/24/01 SERIAL NUMBER: LD01413018

IntelliFlow FSCAB100BXLR

IntelliFlow Digital Flow Products MODEL NUMBER FSCAB100BXLR GAS: CH3F RANGE: 50 REF: SCCM SELECT: DATE: 11/07/01 SERIAL NUMBER: LC01403018

IntelliFlow FSDAB10014LR

IntelliFlow Digital Flow Products MODEL NUMBER FSDAB10014LR GAS: CHF3 RANGE: 100 REF: SCCM SELECT: DATE: 10/15/01 SERIAL NUMBER: LD01393044

IntelliFlow A331245001

Mykrolis IntelliFlow Adapter A331245001

Some sort of adapter accessory that fits on the other Millipore meters. Converts it from a HD15-M to a card edge connector? Maybe to ease upgrading legacy systems?

Have 3 of these (one for each adapter)

Connectors:

- Card edge

- DB15-F

- 2x RJ-11 jack

- 2 pos DIP switch

IntelliFlow pinout

Other sections of the manual indicate +15V

Shielding

Sounds like the basic

electricalfun.com

" Q. What types of radiation do you need to be concerned about?

A. When operating a fusor, you need to be aware of two types of radiation: fast neutron radiation caused by the fusion reaction, and bremsstrahlung x-ray radiation caused by the slowing down of electrons. The primary cause for concern is the x-ray hazard, X-rays will begin to shine through viewports and other glass surfaces at around 12,000 volts of input voltage (this is why cameras and mirrors are used to look through viewports), and they will begin to penetrate stainless steel at around 40,000 volts. At the point that they begin to shine through anything, it is wise to shield that area with lead. Generally for most fusors, neutrons are not typically a worry unless you run your reactor to the point where it emits multiple hundreds of thousands of neutrons per second. At that point, it is usually wise to shield the fusor with a shield made of parrafin wax or boron dissolved in water."

fusor.net

"Thus, 6cm of lead will offer about a 50% attenuation of incident neutrons of up to 5 mev of energy. "

"I have posted a number of times here on the proper shield of borated paraffin which is easily made by the amateur. I purchased 100lbs of parrafin from Missey's Candles online for $68.00 and 30lbs of Borax from Grainger for $29.00. I made up a simple shield of small size as a test and never built the big shield as the neutron numbers and need for protection just was not there. (see my post of 2/13/02 for more discussion)"

"My advice is, save your money until you have a real flux. Shielding is a non issue until you are producing 10e6 isotropic neuts/sec and running your machine daily for protracted periods."

Neutron detectors

2015-10-25

SNM-32

Resistor limited current in SNM-32 but still couldn't get it to detect anything. My memory indicated that these are also sensitive to gamma rays (maybe BF3?) so I tried to trigger it with U. Neither with that nor background did I see anything that separated it from noise.

Tried the other tube that was still NOS (the first tube I might have put excessive current into and damaged).

Maybe I need a filtering capacitor?

Read up more on He-3 detectors and then post on forum if I'm still stuck

Ordered banana jacks to make proper holders

Setup: [8]

2015-10-26

Although I've pumped down the chamber in the past, its unclear if I actually have the interconnect (especially efficient interconnect) to connect the proposed setup. Need to:

- Make a vacuum schematic

- Ensure I have connectors for all the components. In particular:

- To D2 tank

- MFC VCR

- Tank pressure is 355 PSIG

368407-10L bottle

- CGA 110/180 valve

- " Diffusion resistant, diaphragm seal, packless on/off valve. 3/8 in. NPTM valve thread. CGA 180M/110F outlet connection. "

- Al-Si-Bronze

- NPT male 3/8"

- D25030004

Made system diagram: [9]

Regulator

- Veriflo Corp

- P/N IR400K3pFSMMF

- 2x VCR-14M

- Has: Millipore COCM9829 WGFG01HR1

2015-10-31

Milestones

Should vacuum exhaust also have an MFC? Better flow control but may need more valving to efficiently support

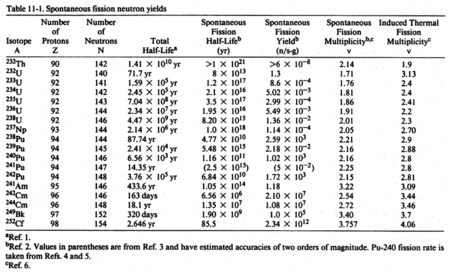

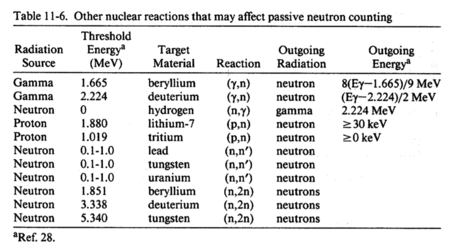

Evidently Am-241 puts off a lot of neutrons by itself. Given that, why do people use it with Be? Does it slow or multiply the reaction? Be is a neutron reflector.

Probably this:

However, the (y,n) threshold energies for beryllium (1.66 MeV) and deuterium (2.22 MeV) are anomalously low. Thus, it is possible to c~ate a photoneutron source by surrounding relatively intense, long-lived, high+mergy gamma-ray sources such as 12bb or ‘6Ra with a mantle of beryllium or D20.

For accountability or safety purposes it is often important to have sources that contain little or no plutonium or uranium. ... Sources that emit random, uncorrelated neutrons can be manufactured by mixing alpha emitters such as 238Pu Or 241Am with beryllium, lithium, fluorine, or other elements in which (~n) reactions are pos8ible

The 241AmBesources are compact and relatively inexpensive and do not require much gimma-ray shielding. However, the high-energy spectrum permits (n,2n) reac- tions that will produce coincidence counts. The 241AmLisources are less compact and more expensive and require tungsten shields. Because of their low-energy neutron spectra, they are the most widely used sources for subthreshold interrogation in active assay and for random-neutron check sources in passive coincidence counting.

2015-11-01

Power

Fusor grid power requirements?

http://robofusor.aditl.com/robofusor-2/nuclear-fusion/

- On July 26th, a 2-minute count of 1373 was recorded, at 18.6 KV, 3.9 mA and a pressure of 12.36 microns. This corresponds to over 5000 neutrons per second.

http://www.so-little-time.com/content/fusor

- A typical fusor operates in the 20 KV to 50 KV range and between 5 and 50 mA.

https://en.wikipedia.org/wiki/Fusor

- Turkish Atomic Energy Authority In 2013 this team built a 30 cm fusor at the Saraykoy Nuclear Research and Training center in Turkey. This fusor can reach 85 Kv and do deuterium fusion, producing 2.4×104 neutrons per second.[33]

http://robofusor.aditl.com/robofusor-2/equipment-supplies/high-voltage-power-supply/

- 0 - 10 kV @ 10 - 30 mA. Used NST 15 kV @ 30 mA

Current NST will be difficult to re-ground output due to potting. I believe this limits it to 7.4 kVDC peak @ 60 mA max (either, not both). Will need to be multiplier if want higher voltage. This may be good enough for some quick initial testing

Wiring is also a little fuzzy to me. The center tap on case is isolated with plastic implying that it might already be isolated.

Commercial PS supply survey. Result: expensive. See how far current NST gets us than reevaluate. Most likely will get a different NST or try to push the grounding.

Detector

Still having trouble getting SNM-32 to work. Got some things that sort of look like pulses but they may have been caused by loose connection. Made a basic socket to try to improve contact.

Tried to replicate this schematic as close as I could: http://www.fusor.eu/monitors.html#neutron_detector

but still no dice. Going to reach out for help.

Successfully ran an SBM-20 on my scope to demonstrate I understand detector tube fundamentals. Output voltage lower than expected => tube has much higher conduction resistance that I was expecting but did work. Expected 5V but only got 900 mV. Maybe the He-3 really is that small of signal?

Starting to look up info for the Scionix detector as an alternate. Guide claims you can solder connections...maybe I just need to heat it more?

Mini maker-faire

Asked to present something on Friday and fusor seems like a good demo. Try to get a non-nuclear star mode demo

2015-11-02

GOAL: see how far I can get assembling vacuum hardware for plasma demo

Discovered that I'm missing a CF133 to KF16 adapter in the schematic. Consequently I didn't order one and I don't happen to have one on hand.

Cleaned and greased roughing system

Ordered misc hardware: pump vibration isolation, more 8-32 bolts

2015-11-03

Thought some about layout. Separable modules:

- Roughing: pump, traps, air release, some measurement

- Chamber: chamber, D2 tank, MFC, regulator. Two level:

- Top: D2 bottle, regulator, MFC

- Bottom: chamber

- HV: NST, diodes

- Variac. Metered?

- Agilent PS to control MFC

Roughing, chamber separation: KF16 flange. Elastomer seal can be broken and re-made easily

Chamber will be faced towards front with NST behind it. Variac will be next to chamber, possibly on top of Agilent PS

Cut pump chassis t-slot. Need to think out chamber chassis before cutting

A bunch of hardware should arrive tomorrow to complete pump unit

2015-11-04

Cut chamber frame. Assemble pump frame and chamber frame

Lost on t-slot brackets but should have enough

2015-11-05

Conflat torque spec: http://www.lesker.com/newweb/flanges/flanges_technicalnotes_conflat_1.cfm

- 1.33: 7 ft-lb => 84 in-lb

waaay too high. This is much better: http://mtm-inc.com/reduce_project_risk/proper_torque_for_conflat_flange_bolts/

- Need to read this in more detail

- Recommends 20 in-lb for 8-32 bolts on Cu gasket?

- 8-23 typo...

2015-11-06

Mini-maker faire demo at barns and noble

2019-04-29

Recent interest from Rob, rebooted some things

General feedback from people at party a few weeks ago:

- Make inner electrode smoother. Its probably the cause of the arcs

- Consider removing outer electrode. It probably doesn't do anything

- Smaller MFC (say 50 SCCM => 5 SCCM)

Some tests a few days ago swapped in new MFC (Hitachi SFC1470FP1 / MC-4VLW241 5 SCCM), but was unable to get it flowing. Complication: it requires +/- 15V, and no longer provides a 5V reference. I now have AD 704 supply to try to get off of the benchtop supply. Ordered 7805, will arrive in a few days.

TODO:

- Troubleshoot new MFC. Why can't I get it to actuate? Check output voltage

- Test, cable AD 704

- Proper HV connector

MFC on benchtop supply

- +15V: 70 mA

- -15V: 100 mA

- Green light blinks

Got MFC working. Valve full open w/ turbo + scroll pump backing => 4.0E-2. With valve closed get around 2.0E-3 (unclear if turbo is bad or gauge can't read low well). Can probably close a downstream valve if I want to raise pressure further